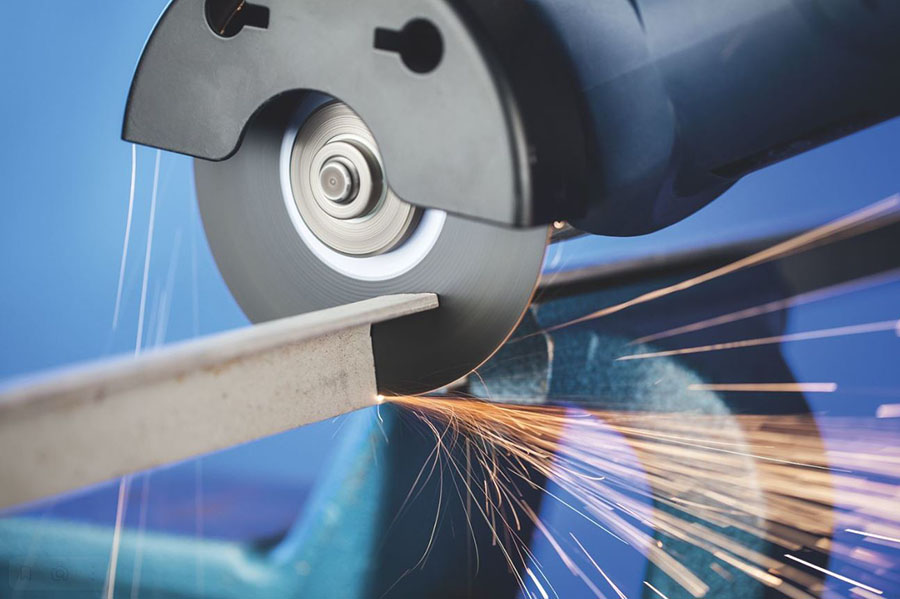

The grinding disc is a flexible tool that is essential for obtaining accuracy and flawless finishes in the field of industrial machining. However, if not used with the utmost care, this adaptable equipment has inherent safety dangers. Industrial employees must hone the skill of using grinding wheels securely and effectively, just like an artist hones their artistic ability. Applying safety procedures while utilizing grinding wheels is essential because they serve as a benchmark for balancing workshop security and possible threats. Join us as we examine the essential rules for maximizing polishing disc efficiency while guaranteeing the safety of the workshop workers.

Examine and Confirm the Wheel

Examine and confirm the condition of the grinding disc before beginning any grinding work. Make sure it is free from flaws or damage, and store it somewhere dry. Additionally, do a ring test on the disc to look for any flaws. A bright, bell-like tone denotes safety for usage, whereas a dull resonance signals possible problems.

Pick the Grinding Wheel Carefully

It is impossible to overestimate the skill involved in matching the material of the workpiece with the grinding wheel. Incompatible wheels can result in poor finishes, slowly removed material, and even disc fracture. To achieve a fluid and efficient grinding operation, always use judgment.

Sync Up the Machine and Grinding Wheel Speeds

It is crucial to match the machine’s speed and the rate of the grinding wheel. Avoid exceeding the maximum speed limit, since it may result in accidents and injuries. This limit is marked on the wheel.

Maintain Surface Speed Limits

Observe the designated surface speed limitations that are written on the wheel. It is crucial to test the balance of freshly attached wheels for at least one minute at operational speed in order to prevent thermal cracking.

Avoid Using Too Much Force When Mounting Wheels

A grinding disc may be put under excessive stress when being forced onto a machine, perhaps leading to cracks or fractures. Avoid widening the mounting aperture since doing so might cause instability and vibrations when grinding.

Use Care When Tightening Nuts and Screws

Keep the nuts and screws from being over-tightened while mounting the wheel. Over-tightening can cause the wheel to distort and become unbalanced, which opens the door to breaking.

Before Stopping the Wheel, Reduce Coolant Flow

Prior to halting the grinding wheel, the coolant flow must be stopped. This safety precaution keeps the coolant from soaking into the wheel’s pores, maintaining its effectiveness.

Personal Protective Equipment (PPE) Should Be Given Priority

Your armor against the risks of grinding is called personal protective equipment (PPE). Put on your face shield, safety glasses, and hearing protection. When using grinding discs, observing PPE guidelines should always take precedence.

Keep the Cutting Edge of the Wheel Sharp

Its cutting effectiveness must be maintained with routine wheel dressing. This procedure involves removing worn-out abrasive grains, improving performance, and extending the wheel’s useful life.

Refuse to Side Grind Without the Appropriate Authorization

Understand the grinding wheel’s construction and intended application. Unless specifically permitted, avoid side grinding. Fragmentation caused by improper use of a grinding disc can pose serious risks to users and those nearby.

Finale

The art of using grinding discs effectively combines accuracy, safety, and efficiency. Workers may foster a safe and effective working environment by rigorously following safety regulations. Always keep in mind that strict adherence to these fundamental rules is essential for both your safety and the safety of your coworkers. Put these ideas into practice when you start your next arduous task. Keep yourself safe, work efficiently, and let your knowledge of industrial grinding shine. Trust MEF Industrial Solutions with all of your needs for grinding discs and industrial solutions.

Hiking addict, shiba-inu lover, record lover, Swiss design-head and New School grad. Acting at the crossroads of modernism and sustainability to craft an inspiring, compelling and authentic brand narrative.